Machine tool builder, Soraluce, recently hosted the “Soraluce Summit” at its Bergara, Spain, facility to celebrate 60 years of building

Soraluce’s factory played host to its Soraluce Summit, May 18-20, 2022. Visitors had the opportunity to see machine demonstrations and tour the factory where the machine tools are assembled. Photo Credit: Soraluce

Soraluce, part of the Danobat Group, builds turnkey and custom large-format milling, boring and multitasking machine tools. The company is known for making big machines with work envelopes that often exceed 10,000 mm on the X-axis and up to 8,000 mm on the Y-axis. Milling machine configurations include bed type, floor type, portal, gantry and duplex — all of which can be customized based on customer needs. The company also offers turnkey services and fast-delivery machines. In the U.S., Soraluce is distributed by Select Machining Technologies, a division of Morris Group, Inc.

During my visit, I was provided with the opportunity to see and feel exactly how Soraluce has optimized its machines to make large-format machining faster while improving the usability for operators.

Hardware and Software Work Together

When it comes to machining parts that are several meters long and equally tall, throughput often comes second to accuracy and integrity of the part that is being machined. Given the volume and cost of raw material for large parts,

- Dynamic Workpiece Stabilization (DWS). When a workpiece has features that are thin and flexible, the resonance produced by machining can impact the surface finish of the part. Soraluce has developed a patented system that counteracts the resonance with equal and opposite mechanical force through a module that is connected to the part by magnet or vacuum holding. The system can be activated on command, as necessary, from the control panel. As the computer senses chatter, it sends a signal to the module to compensate with an inverse force. This provides targeted reduction in chatter.

The company offers a wide array of technologies to improve large part machining. In this photo, an operator is demonstrating how to attache a Dynamic Workpiece Stabilization (DWS) module to a non-ferrous part with its vacuum plate. Photo Credit: Soraluce

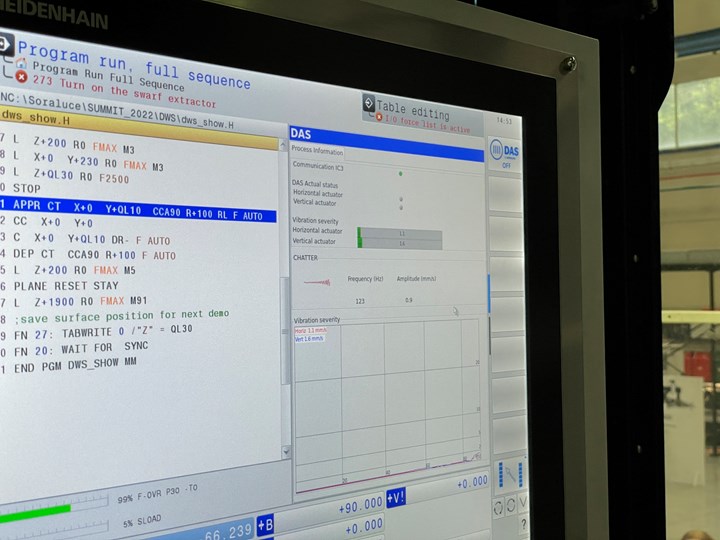

- Dynamic Active Stabilizer (DAS). Like DWS, DAS is a dampening system that involves the entire machine tool. The system is comprised of hardware in the machine and software that analyzes feedback from the spindle. Inside the ram of the machining center there are actuators that provide mechanical compensation for chatter. The actuators are controlled by software algorithms that also automatically regulate spindle speed to eliminate chatter at the press of a button.

DAS can be activated via the machine control in the operator carriage or from a wireless pendant outside of the machine. Photo Credit: David Lyell

I had the opportunity to ride along in the operator carriage on a floor-type machining center for a demo of the feature. The operator started a heavy cutting operation that produced a lot of feedback, and it was obvious by the sound of the cut that the tool was chattering. He instructed me to press the DAS button and the machine instantly eliminated the chatter. No modification of the G-code was necessary. The company says that this feature can improve productivity by 300%.

- When touring the machine head assembly area, we saw a sample of the wide array of heads that Soraluce offers. The company offers 300 head configurations, everything from straight boring heads to five-axis heads. An impressive option on its machining centers is a head storage center where the machine can exchange heads. The towers can be configured from 2 to 4 spaces. The ability to change heads on the fly further reduced the need to move a large part from machine to machine, improving productivity.

Automatic head swapping is achieved with an optional head tower that docks heads that are not in use. Photo Credit: Soraluce

In addition to these observations, the company demonstrated several other technologies like “My Soraluce”, a machine monitoring suite; Autocheck, a machine diagnostic system, and more. We also visited IDEKO, a regional research center that is part of the Danobat group that hosts more than 140 engineers (including many PhD-level scientists) who are pushing the boundaries of manufacturing science. You can read more about the technologies that Soraluce offers on its website, and view a tour of the company’s assembly facility in the video below.

https://www.youtube.com/watch?v=dwseEW5HkZg

RELATED CONTENT

-

A New Milling 101: Milling Forces and Formulas

Part 3. The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality (and the profitability) of milling operations.

-

How to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

-

Rolling Threads Has Advantages

With macros and canned cycles resident in the CNC on most contemporary turning centers, single point turning of OD threads can seem like almost a default process decision. However, for numerous applications, OD thread rolling has inherent advantages as an alternative to cutting threads.

More Stories

SOLID Design Principles in C# with helpful examples

7 Reasons To Get A Forbrukslån & How To Get A Good One

8 Tips to Optimize Your SQL Queries for Improved Database Performance