The invisible Conductor: Why Frequency Conversion Is Essential in Modern Electrical Systems

In the early days of the electrical age, the world was divided by more than just borders; it was divided by standards. As power grids began to spread across continents, different regions adopted different frequencies for their alternating current systems. Most of the Americas settled on sixty hertz, while much of Europe and Asia opted for fifty hertz. For decades, these systems lived in relative isolation, but the dawn of the globalized industrial era changed everything. Today, the ability to change the frequency of electrical power is not just a technical convenience; it is the backbone of modern automation, renewable energy integration, and global trade. Visicomm Industries frequency converters allows us to bridge the gap between incompatible grids and, more importantly, to control machinery with a level of precision that was once thought impossible.

Precision Control in Industrial Automation

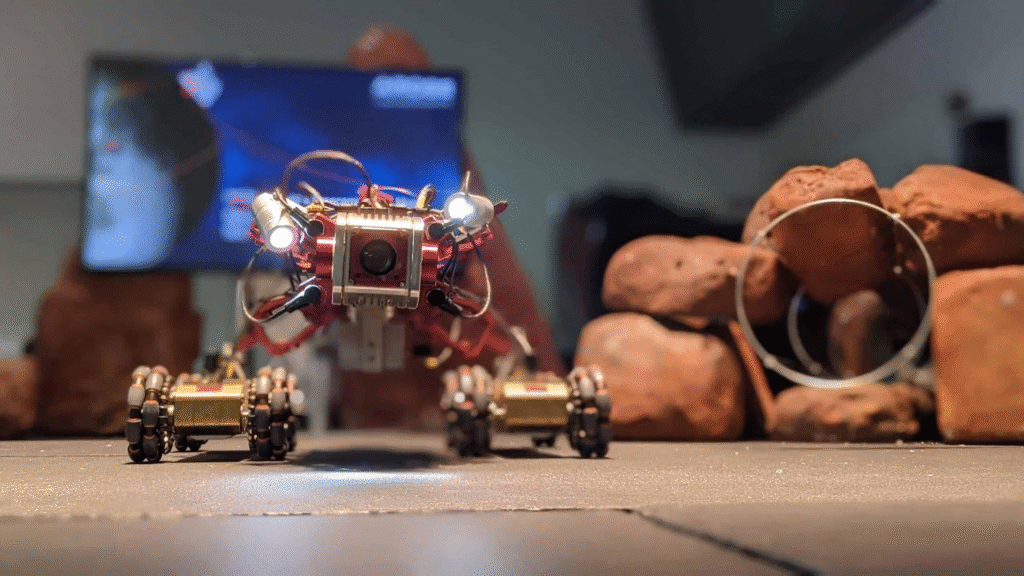

The most visible impact of frequency conversion is found on the factory floor. Historically, industrial motors ran at a fixed speed determined by the frequency of the power grid. If an engineer needed a pump or a fan to slow down, they had to use mechanical means like gears, belts, or valves. This was inherently inefficient, as the motor continued to pull full power even when the output was being throttled. The introduction of the Variable Frequency Drive, or VFD, revolutionized this process. By converting the incoming fixed-frequency power into a DC signal and then reconstructing it into an AC signal at whatever frequency is needed, these devices allow for infinite control over motor speed.

This level of control is essential for delicate manufacturing processes. In a bottling plant, for instance, conveyors must accelerate and decelerate smoothly to prevent breakage. In textile mills, the tension on the yarn must be kept perfectly constant to ensure quality. Frequency conversion provides the responsiveness required for these tasks. Beyond just speed control, it also allows for soft-starting heavy machinery, which reduces the mechanical stress on the equipment and prevents the massive spikes in electrical demand that can destabilize a local power network. By matching the electrical frequency to the mechanical requirement of the task, we have made industrial processes faster, safer, and more reliable.

Maritime and Aviation Applications

The importance of frequency conversion is perhaps most evident in specialized environments like ships and airplanes. Many aircraft and naval vessels operate on four hundred hertz power systems rather than the standard sixty hertz found on land. This higher frequency allows for much smaller and lighter transformers and motors, which is a critical advantage when every kilogram of weight affects fuel efficiency and performance. However, when a ship docks or a plane is parked at a gate, it must connect to the local land-based power grid to keep its systems running without burning its own fuel.

Shore-to-ship power systems and ground power units for aircraft rely entirely on frequency conversion. These units take the local grid power and convert it to the specific frequency required by the vessel’s onboard electronics. This not only allows for a seamless transition between mobile and stationary power but also significantly reduces local air pollution and noise at ports and airports. Without this technology, global transportation would be much louder, dirtier, and far less efficient. The ability to harmonize disparate electrical standards ensures that the global logistics chain remains unbroken, regardless of where a vehicle was manufactured or where it is currently located.

Conclusion

Frequency conversion is the invisible thread that sews together the various patches of our modern electrical world. It is the technology that allows us to bridge the gaps between international standards, harness the power of the wind, and drive our factories with surgical precision. As we look toward a future defined by smarter grids and more complex industrial needs, the role of the frequency converter will only become more prominent. It has evolved from a niche engineering solution into a fundamental pillar of global infrastructure.